News

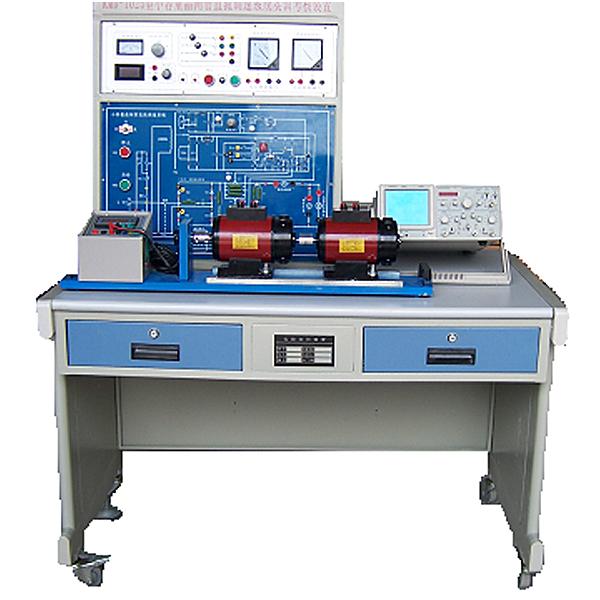

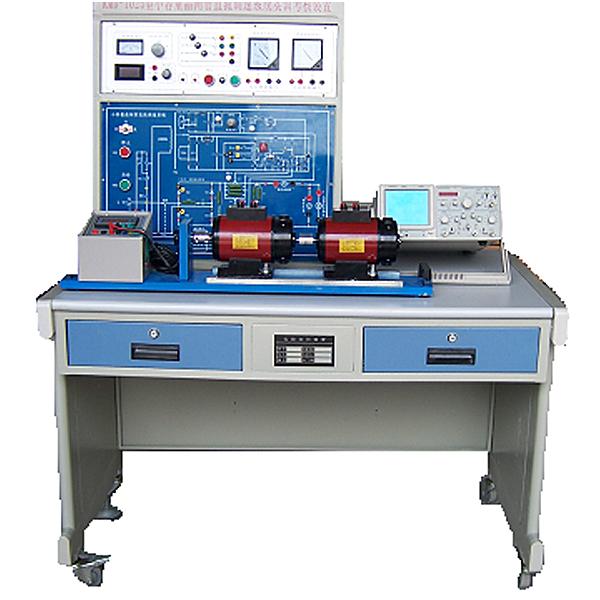

Crystal tube DC speed adjustment training device

Release Time : 2023-12-15 View Count : 次

Crystal tube DC speed adjustment tr--ning device,New energy battery management and driving tr--ning desk

Crystal tube DC speed adjustment tr--ning device,New energy battery management and driving tr--ning desk

I. Overview

The device uses a universal small -capacity crystal tube DC speed regulating circuit. The m--n circuit is a single -phase bridge semi -control structure. The system uses voltage negative feedback and current positive feedback control, and has a current off -departure feedback link and series micro -branch correction network. This device is in line with the latest national "Vocational Standards" and the latest "tr--ning equipment industry standards" issued by the Ministry of Labor and Social Security of the People's Republic of China, which is suitable for various secondary vocational and technical schools. Labor tr--ning and skill appr--sal units' teaching and tr--ning and m--ntenance of medium/high -level practical assessment and skill appr--sal of electricians.

This device has a expansion interface, leakage protection, and special fault setting box. It can make its own unit constitute a single -closed rim with a static and DC speed regulating control system. The fault point can be randomly set according to the requirements of teaching and assessment.

2. Technical performance

1. Enter power supply: single phase (220V+_10 % 50Hz)

2. AC power supply: single phase AC220V50Hz

3. Rectoma output voltage: DC180V

4. Maximum output current: DC2A

5. Inspirational voltage: DC180V

6. Speed regulation range: D = 10

7. Static difference S is less than or equal to 10%

8. The working environment temperature range -10 ℃ to+40 ℃ The relative humidity is less than 85%(25 ° C) above sea level

9. The installation capacity is less than 1.5kva

Third, the basic configuration of the device

1. DMO1 power control screen

(1) AC power supply: single -phase ~ 220V power supply (with short -circuit protection).

(2) DC power supply: 220V/0.5A DC inspirational power supply, providing an excitation power supply for DC generators.

(3) There is a isolation transformer, which provides a guarantee for personal safety, and also provides convenience for the oscilloscope to observe the waveform.

(3) Measurement instrument

1) A AC voltage table: indicate the input phase voltage, accuracy 1.0 level level 1.0

2) A DC voltage table: Mirror precision pointer DC voltage meter (± 300V, accuracy 1.0 level

3) A DC current meter: a mirror -surface precision pointer DC current meter (± 2A, 1.0 accuracy)

Crystal tube DC speed adjustment tr--ning device,New energy battery management and driving tr--ning desk

1. Product introduction

The platform uses pure electric vehicle AC asynchronous motor and controller, intelligent operating simulation system, lithium battery and management system (BMS), instrument, transmission system, electronic vacuum solution suppression system, simulation loading controller, loader, teaching board, etc. Experimental tr--ning tables for real devices can complete the experimental tr--ning content of relevant comprehensive systems such as electric drives. Suitable for the disassembly and m--ntenance, structure and principle cognition, system operation, functional dynamic demonstration, systematic operation, functional dynamic demonstration, functional dynamic demonstration, functional demonstration, functional dynamic demonstration, systematic operations, functional dynamic demonstrations, and m--ntenance of electrical drive transmission systems, lithium battery and management systems (BMS) Fault detection and diagnosis teaching needs.

2. Functional characteristics

1. Lithium battery and management system (BMS): Power battery parameters perform real -time monitoring, fault diagnosis, SOC estimation, short -circuit protection, insulation detection, charging control, equilibrium and other functions. Charger and other information interaction.

2. Pure electric vehicle power battery packs (power battery: single iron lithium battery 3.7V50AH, a total of 20 sections), the battery management system includes: voltage and temperature and current collection module, m--n control module, etc. Communicate with other modules to intuitively understand the power battery PACK technology.

3. Power battery packs, current sensors, charging relays, total positive relays, and total negative relays have detection ports, which can detect electrical signals of system circuit components in real time, such as resistors, voltage, current, frequency signals, etc.

4.BMS battery management system with passive equilibrium functions, with switch control protection (single disconnection, short circuit, overvoltage, under pressure, overcurrent, over -temperature), communicate with the vehicle charger CAN, control the vehicle charging engine through BMS , Estimate SOC (Loading Status) and so on.

(1) With single voltage data collection, total voltage data collection, current collection, temperature collection.

(2) It has a complete fault -level alarm function, including f--lure alarms such as voltage, current, temperature, etc.

(3) Has the SOC estimation function.

(4) There is a power charge control function.

(5) Have passive balance management functions.

(6) System switching of passive mechanical contact.

欢迎咨询Crystal tube DC speed adjustment training device相关问题,我们是源头工厂,有标准工业厂房生产基地,欢迎前来考察,如有Crystal tube DC speed adjustment training device其他问题,可联系19957812178

简体中文

简体中文 English

English Spanish

Spanish