News

Material Category Experiment

Release Time : 2024-01-04 View Count : 次

Material Category Experiment,Gasoline engine electrical control system experiment table

Overview

Material Category Experiment,Gasoline engine electrical control system experiment table

Overview

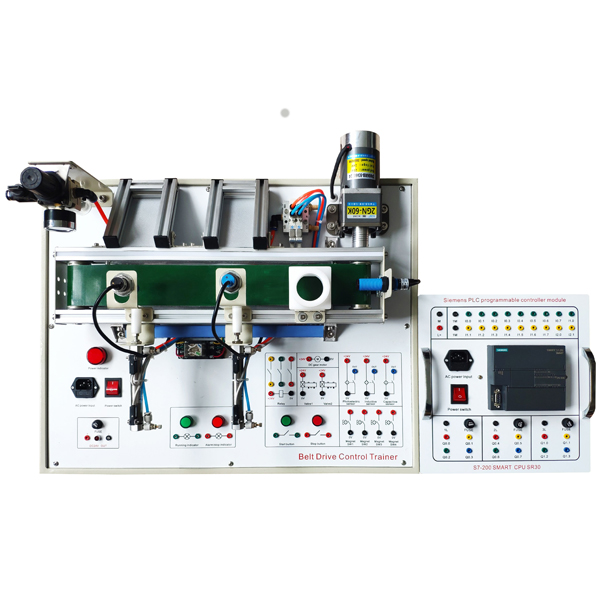

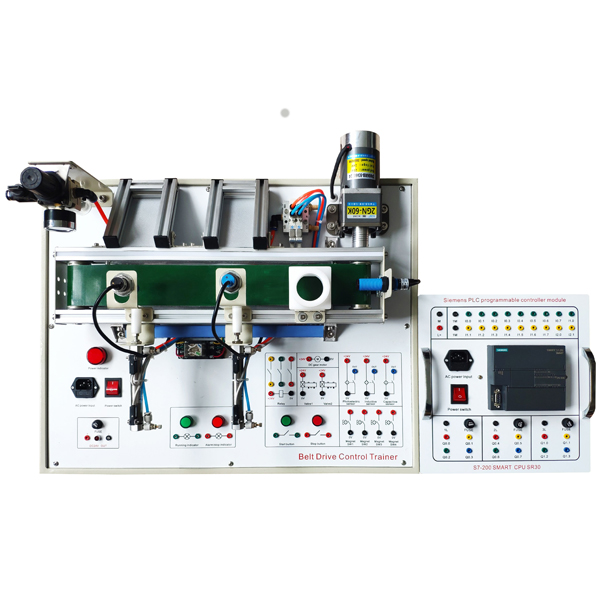

This experimental equipment should include teaching content such as pneumatic control, motor transmission, electromagnet control, location control, sensor detection, etc., which is a micro -shrinking device for actual industrial site production equipment. The system should be based on the detection of a variety of sensors to achieve sorting of different materials and different color objects. Adopt a full open layout to exercise the ability of the operator system wiring, mechanical debugging and installation, software programming, independently construct control system, feedback settings, fault detection and m--ntenance.

2. Features

1. Equipment and device consists of six parts such as the bottom plate, tr--ning table (profile structure), pneumatic part, feeding mechanism, material transmission mechanism, material groove and electrical control. The pneumatic part consists of a solenoid valve and a cylinder, and the material transmission part consists of a motor and a synchronous conveyor belt.

2. Electrical control consists of single -phase AC motors and reducers, solenoid valves, cylinders, switching power supplies, photoelectric sensors, capacitor sensors, inductors, magnetic sensors, etc.

3. Collect with sensor signals, PLC programming, and control motors, solenoid valves, switching control, setting control, and timing logic control to achieve positioning, identification, and classification of materials on the conveyor belt.

3. Technical parameters

1. Enter power supply: single -phase three -line ~ 220V ± 10% 50Hz 50Hz

2. Qi source: 0.2MPa ~ 0.55MPa

3. Working environment: temperature -10 ℃ ~+40 ℃ relative humidity ≤85%(25 ℃) Altitude <4000m

4. Tr--ning device capacity: <0.5kW

Fourth, device composition

1. Equipment and device structure with a profile bottom plate structure

2. The pneumatic part is composed of pressure regulating filter valves, solenoid valves, speed regulating valves, cylinders and magnetic switches, and --r pumps

3. The material transmission part consists of a single -phase AC motor, a reducer and a synchronous band

4. Composition of sensors include photoelectric sensors, capacitor sensors, inductor sensors, magnetic sensors, etc.

5. Tr--ning project

1. Single -phase AC motor positive reverse control

2. Sort out black and white blocks

3. Debugging of the material sorting system

4. Sort out red and white blocks

Material Category Experiment,Gasoline engine electrical control system experiment table

1. Product introduction

The device uses the real parts of the engine electrical control system to fully display the composition and working process of the engine electrical control system.

It is suitable for the teaching needs of school theory and m--ntenance of engine electrical control systems.

2. Functional characteristics

1. Real and operating engine electrical control system, simulate the operation of the engine crankshaft, can produce the work of spark plug ignition, fuel pump work, fuel injection, and other execution components, fully display the structure and working process of the engine electrical control system.

2. The teaching plate panel adopts high -grade aluminum -plastic panels with strikes, pollution resistance, fire resistance, and moisture -proof, and sprayed on the surface by special crafts; panel prints with color circuit diagrams that never fade and work. Circuit diagrams and physical objects, understand and analyze the working principle of the engine electrical control system.

3. Detective terminals are installed on the teaching panel, which can directly detect the electrical signals of the electrical control system circuit component on the panel, such as resistance, voltage, current, frequency signal, etc.

4. Diagnostic seats are installed on the teaching board panel, which can be connected to a dedicated or universal car decoder to read the engine electronic control system of the engine electrical control system and clear the fault code.

5. Demonstration panel parts use 1.5mm cold plate stamping and forming structure, beautiful appearance; the ch--n part is welded with steel structure, the surface is treated with spraying process, a self -locking wheel device, and a desktop on the base of the teaching plate. , Easy to place data, light detection instruments, etc.

6. The work of the teaching board adopts a normal 220V AC power supply. The internal circuit transformer is transformed into a 12V DC power supply. No battery is required to reduce the trouble of charging. The 12V DC power supply has a short circuit function.

7. Machinery assembly and fitter assembly virtual simulation software: This software is developed based on Unity3D. It can select 6 -level image quality. It has the design and virtual disassembly of the reducer and shaft structure, the design and simulation of common mechanical institutions, institutional resource libraries, institutional resource libraries. Typical mechanical institutions (virtual disassembly of gasoline engines), software is an overall software, which cannot be separate resources.

欢迎咨询Material Category Experiment相关问题,我们是源头工厂,有标准工业厂房生产基地,欢迎前来考察,如有Material Category Experiment其他问题,可联系19957812178

简体中文

简体中文 English

English Spanish

Spanish