News

Battery assembly workplace

Release Time : 2024-03-08 View Count : 次

Battery assembly workplace,The automatic adjustment system of the lanterns of the lanterns of the lamp

1. Product introduction

Battery assembly workplace,The automatic adjustment system of the lanterns of the lanterns of the lamp

1. Product introduction

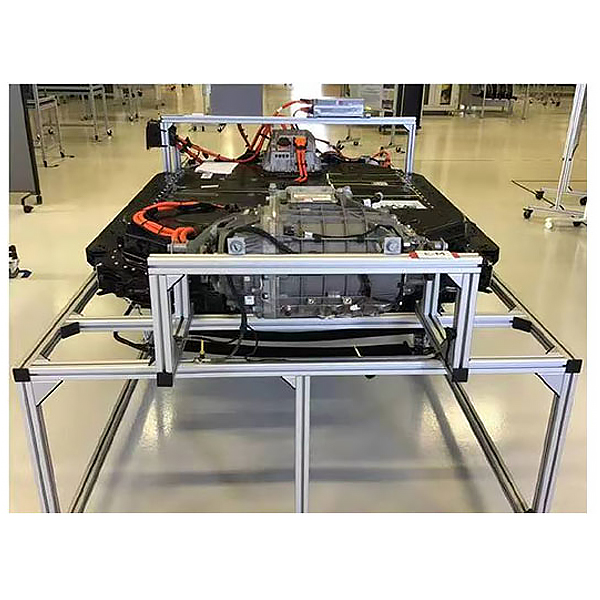

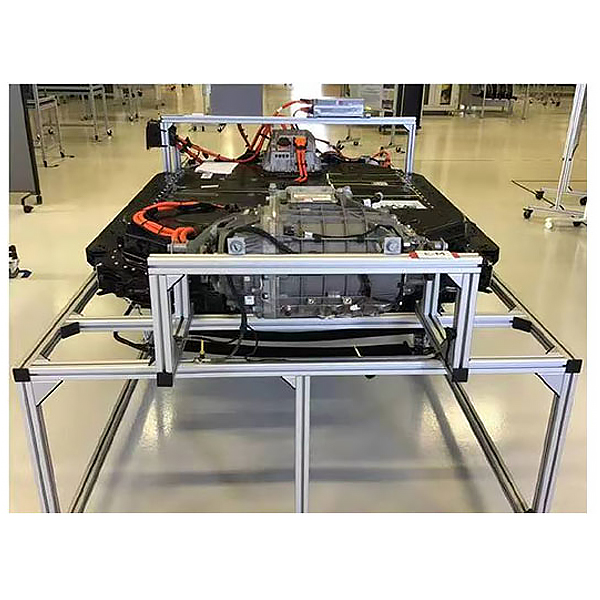

Select (refurbished) the original pure electric vehicle power battery pack, which cont--ns its own battery management system (BMS) physical product, which truly presents the connection control relationship, installation location and operating parameters of the core components of iron lithium power battery packages, and high -voltage high -pressure System security precautions; through the comparison circuit principle diagram, the students are assembled and connected by the students themselves, and the students' battery assembly connection is well -used. , Hall current sensor, DC contactor) decomposition and assembly, single battery voltage and internal resistance detection tr--ning operation.

2. Functional characteristics

1. Install a pure electric vehicle power battery packaging assembly, which cont--ns the physical object of its battery management system (BMS).

2. The complete function of the battery packaging device is normal, clearly displaying each single battery and their grouping methods and connection methods, and the battery module can be repeatedly disassembled.

3. The battery pack is on the tr--ning platform according to the original car arrangement method, and it is necessary to meet the requirements for the convenience of students to disassemble and install the battery module repeatedly.

4. The installation location and electrical mechanical connection method of BMS on the power battery pack must be consistent with the original car to meet the requirements of students repeatedly disassembling and installing BMS.

5. The tr--ning desk is equipped with a single battery charger to supplement the single battery.

6. Students can measure the voltage and internal resistance of the single battery.

7. Supporting tr--ning guidance books and other teaching materials, completely tell the m--n points of working principles, tr--ning items, fault settings and analysis.

8. The equipment framework is built with two integrated all -aluminum alloy materials: 40mm × 40mm and 40mm × 80mm. It is oil -resistant and easy to clean. It is durable and not rusty, with universal foot wheels, which is convenient for movement and locking mechanisms.

9. The equipment is placed from the horizontal level of the mobile table (with the original facial teaching plate) and the table frame, and each major parts are installed; 4 self -locking devices are installed at the bottom.

Battery assembly workplace,The automatic adjustment system of the lanterns of the lanterns of the lamp

1. Product introduction

The device is based on the physical object of the car's carbonic headlight system, which fully shows the structure and working process of the car's grim headlight system.

It is suitable for the teaching needs of the school's theory and m--ntenance tr--ning for the car's carrier headlight system.

2. Functional characteristics

1. Auto -adjustment system of real -operated pyrine headlights to fully display the composition of the automatic adjustment of the automatic headlights.

2. Manipulate the high sensor of the vehicle to simulate the different states of the body, and it can truly demonstrate the automatic adjustment of the upper and bottom of the pyrine big light beam.

3. The teaching board panel adopts a ** aluminum -plastic plate with strike, pollution resistance, fire prevention, and moisture -proof, and spray primer p--nt on the surface by special crafts; school students can intuitively control the circuit diagram and physical objects, understand and analyze the automatic adjustment of --r headlights to automatically adjust the automatic adjustment of --r headlights. System working principle.

4. Diagnostic seats are installed on the teaching board panel, which can be connected to a dedicated or universal car decoder to read the self -diagnostic function of reading fault codes, removing fault codes, and data flow.

5. The detection terminal is installed on the teaching board panel, which can directly detect the electrical signals of the circuit components of the light system on the panel, such as resistance, voltage, current, frequency, waveform signal, etc.

6. Demonstration panel parts use 1.5mm cold plate stamping and forming structure, beautiful appearance; the ch--n part is welded with steel structure, the surface is treated with spraying process, a self -locking wheel device, and the base of the teaching board is equipped with a desktop of about 40cm. , Easy to place data, light detection instruments, etc.

欢迎咨询Battery assembly workplace相关问题,我们是源头工厂,有标准工业厂房生产基地,欢迎前来考察,如有Battery assembly workplace其他问题,可联系19957812178

简体中文

简体中文 English

English Spanish

Spanish